Understanding Your Propane Tank

Propane tanks have a multitude of connections including valves, gauges and other attached appurtenances that look interestingly complex. We'll introduce you to your propane tank in this section and provide explanations for the necessity and functionality of each of these connections. Every single piece and part of a propane tank serves a specific purpose designed for safety and consumer protection.

The primary focus of this section is ASME propane tanks that are filled on site at a residential or commercial installation. If seeking information on DOT cylinders or other bottles, see propane cylinders.

Propane Tank Parts and Fittings

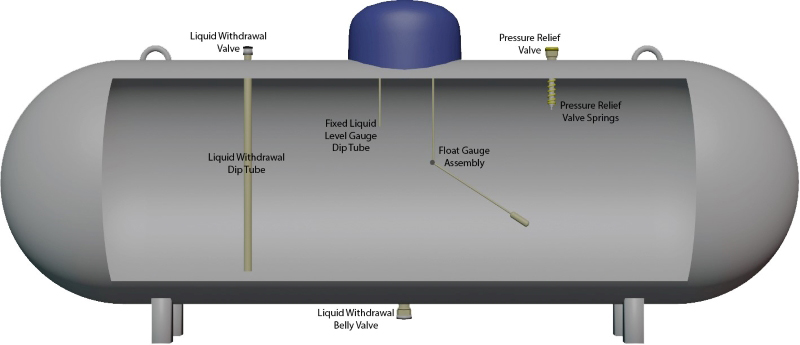

The visible parts of the propane tank as shown in the picture at the top of this page play a vital role in the usability and serviceability of the gas tank and are also shown as installed in the interior of the tank (above). All of these parts are attached to the tank at the manufacturer with threaded fittings. These specialized propane tank parts consist of the following replaceable fittings and connections.

- Fill Valve - Point at which hose from delivery truck is attached to the tank for re-fueling

- Relief Valve - Safety relief mechanism designed to vent propane in an over-pressure situation

- Service Valve - Point at which propane is converted to vapor for use with appliance(s)

- Fixed Liquid Level Gauge - Indicates the level of propane is at or above 80% capacity

- Float Gauge- Presents a visible indication of the propane volume in the tank. Also called a dial gauge

- Vapor Return Valve - Connection used during propane delivery to remove excess tank pressure

- Liquid Withdrawal Valve - Used to withdraw liquid propane from the tank

Propane Tanks Standards

Propane tanks come in many different sizes and are manufactured by many different companies around the globe. These tank manufacturers are required to adhere to the ASME (American Society of Mechanical Engineers) rules for construction of propane pressure vessels intended for use within the United States. The rules in the U.S. are generally more stringent than in other countries with regard to the fabrication of LP Gas pressure vessels. Rules governing the installation of propane tanks are enforced at the national, state, and local levels ensuring all applicable codes and regulations are adhered to for the safety and protection of consumers and the general public. Similarly, propane tank design and appurtenance engineering is undertaken with safety, protection, service and efficiency in mind.

Basic Propane Tank Requirements

Several things that customers should know about their above ground propane tank easily seen without having to know the technicalities of propane tanks and the regulations tanks are subject to. Listed below are simple tank related safety and compliance items consumers can see for themselves without having to know technical details.

- Manufacturers Nameplate - Containers without nameplates are not permitted to be filled

- Tank Paint Color - Propane tanks are required to be painted a reflective color

- Regulator Position - Propane regulator must be covered and protected or pointed vertically down

- Level Placement - The tank must be placed above the soil and on level ground